FELIX and GAMED: Productivity Boost at Privatmolkerei Bauer

Roland Wetzl

23. September 2025

Company Profile

Privatmolkerei Bauer from Wasserburg am Inn is a traditional family business and one of the leading yoghurt producers in Germany. With innovative recipes, high-quality raw materials and state-of-the-art production processes, the company has been combining flavour and quality for generations.

The Privatmolkerei is part of the Bauer Group with high-performance production sites throughout Germany.

“The collaboration with GKC and GAMED has shown how much potential there is in digitalisation. The precise real-time data is now visualised for all employees and can be accessed at any time. This transparent data availability enables us to make faster, more informed decisions when problems arise.”

Christian Braun Head of Operational Excellence

Strong Project Management

Bauer has been using the FELIX software for a long time. After just 6 months, Bauer was able to complete the introduction and integration of the OEE Analyser together with the partner companies.

After an initial intensive test phase on two representative plants, the OEE Analyser was then rolled out and stabilised on all plants, but still without a connection to FELIX. The accompanying training of the production staff ensured a high level of acceptance and the first noticeable improvements. The interface between GKC and GAMED was designed under the leadership of Bauer and went live after implementation.

Thanks to Bauer’s excellent project management and the commitment of the employees, the project was successfully realised in a very short time.

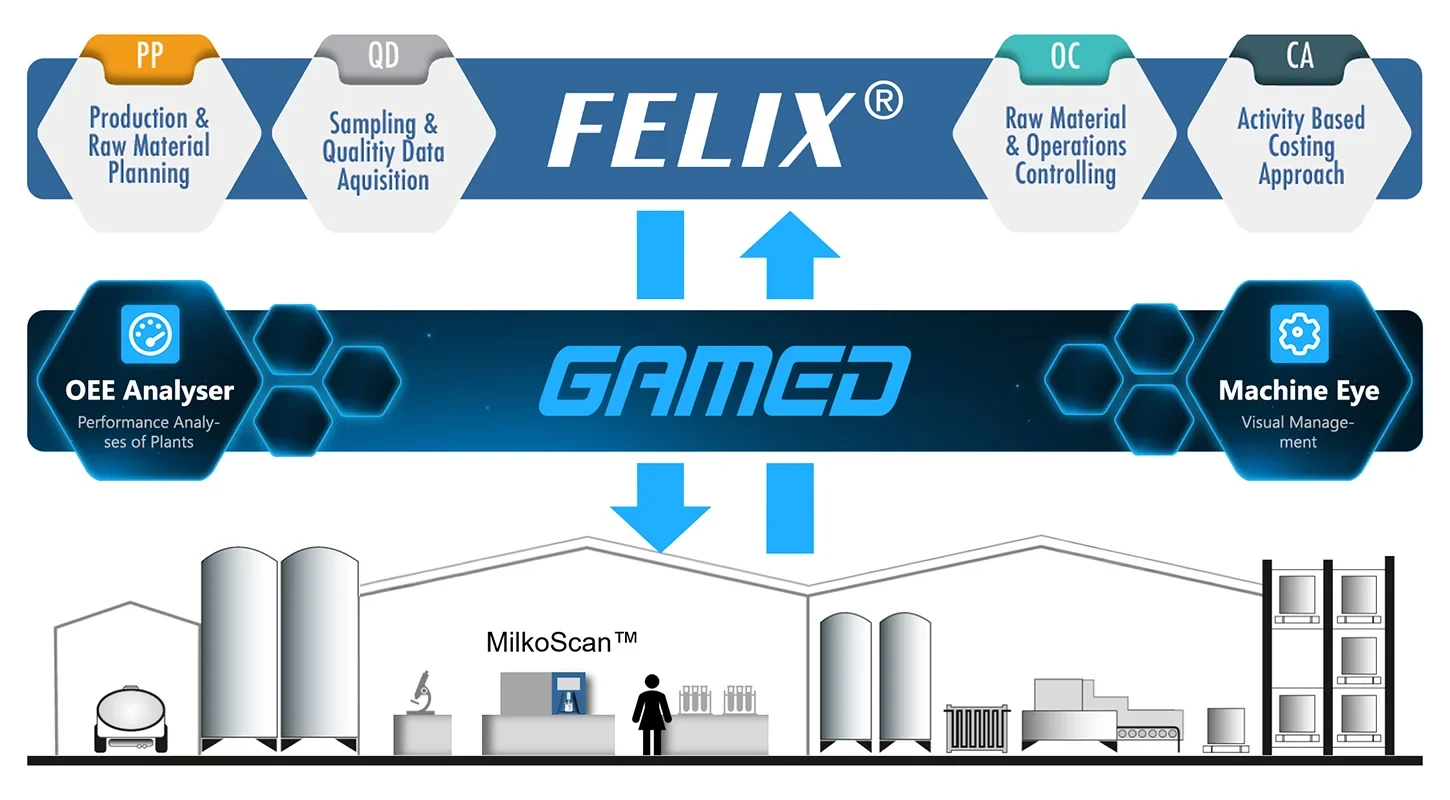

A Strong Duo: FELIX and GAMED

Thanks to the seamless integration of both systems, Privatmolkerei Bauer benefits from end-to-end process management:

- Optimised planning and control: FELIX transfers centralised master data and the planned order sequence for each plant to the OEE Analyser from GAMED. This automates order processing and thus reduces sources of human error.

- Ongoing feedback: During production, the OEE Analyser provides real-time data such as order quantities, speeds and downtimes back to FELIX. This data flows directly into planning and scheduling, making downstream processes such as material provision and plant logistics more efficient.

- Automated checks: In-process checks are reliably triggered and documented. This ensures that quality and conformity standards are met at all times.

- Visualisation for employees and managers: The visualisation of key production figures strengthens employees’ understanding of processes and supports a lean culture. Managers benefit from real-time insights that can be accessed on the move.

The standardised data integration solution is available immediately and gives other companies in the industry access to the benefits of integrated digitalisation.

“Thanks to the seamless system integration, we have achieved measurable increases in efficiency, improved the quality of our systems and at the same time significantly reduced the workload for our employees.”

Christian Braun Head of Operational Excellence

The Result

End-to-end digitalisation of manufacturing processes with clear benefits for operations:

- Increased plant productivity: Optimised planning and control processes have reduced downtimes and set-up times.

- Improved process quality: Automated inspections and real-time transparency ensure consistently high product quality.

- Easier for employees: The intuitive visualisation and simplified workflows noticeably reduce the workload.

- Data-driven decisions: Reliable real-time data enables proactive optimisation and informed decisions at all levels.

GKC AG

The FELIX planning and controlling software from GKC AG has been a proven industry solution for dairies in the DACH region for over 35 years. It supports planning and controlling across the entire value chain. In addition to production and raw material planning with integrated sampling and test planning, functions such as daily raw material and performance controlling, laboratory management, process cost calculation and energy and environmental cost calculation are among the system’s key strengths.

GAMED

For over 40 years, GAMED has established itself as a competent partner for the digitalisation of production – from the conception and introduction to the support and further development of IT solutions. As a leading provider of shop floor solutions, we support SMEs and international corporations in the food, pharmaceutical and automotive industries. At the heart of digital production is our OEE Analyser, which enables productivity analyses, real-time data visualisation, in-process checks and maintenance management.

Your Benefits

- Needs analyses and concept creation

- Lean and flexibly adaptable solutions

- Long-term benefits through maintenance and further development