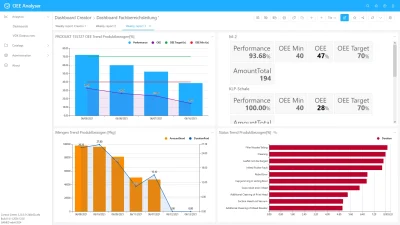

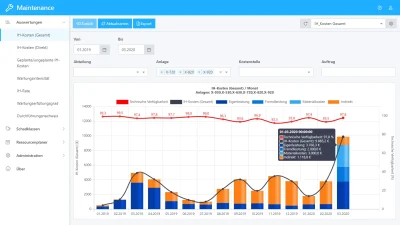

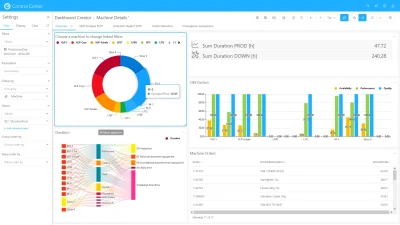

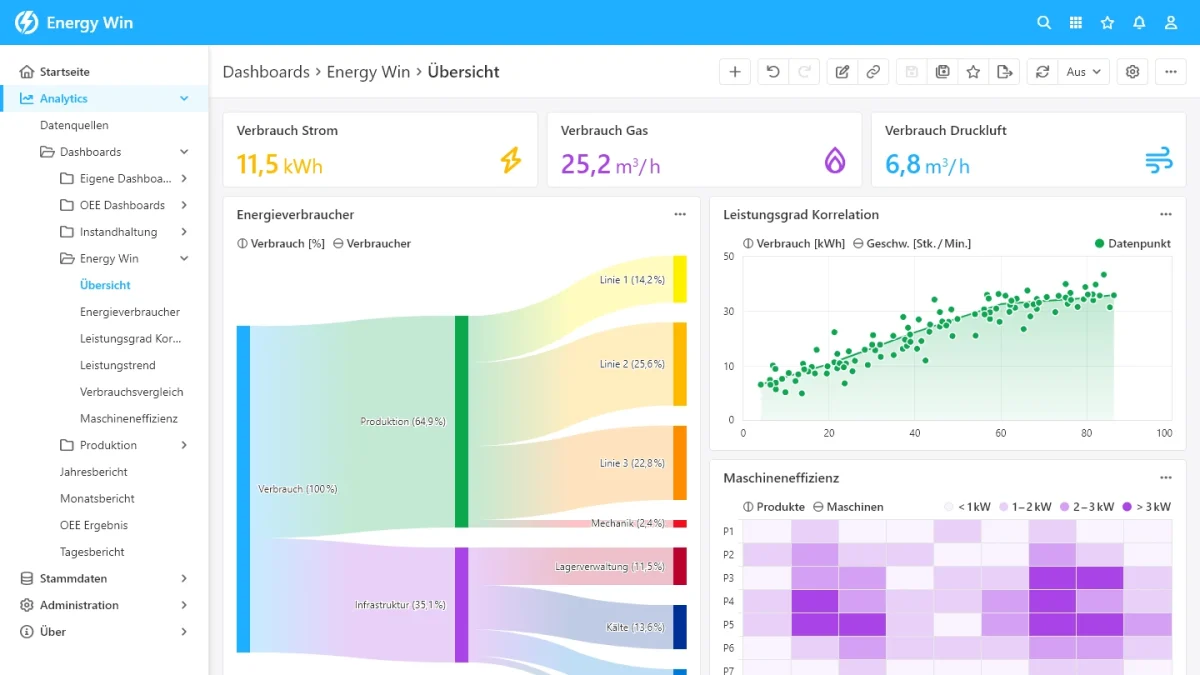

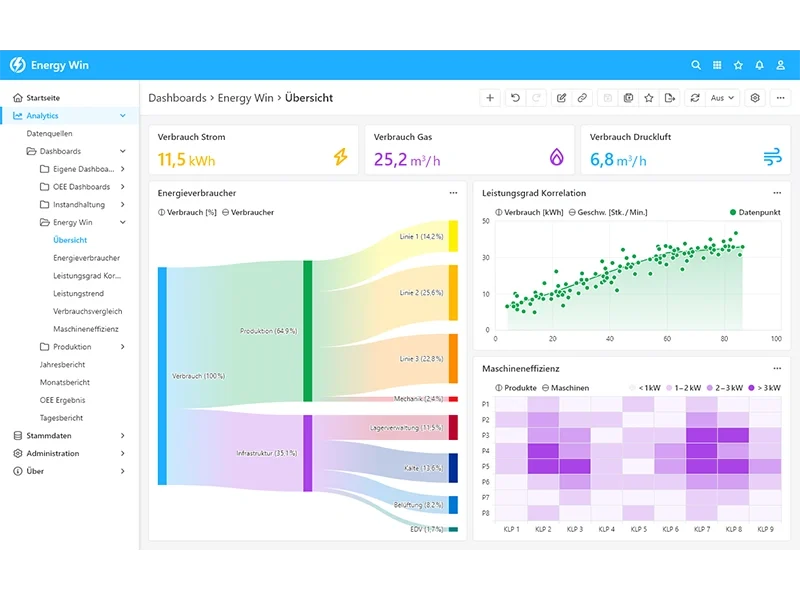

Energy and Consumption Management

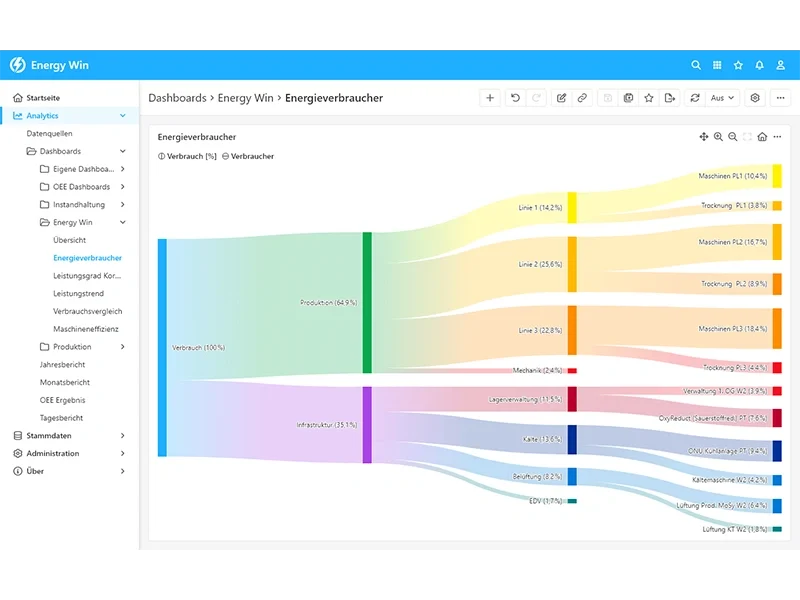

Overview of your energy consumption in real time

Energy and Consumption in Disguise

Energy and consumption costs are crucial factors in manufacturing companies, but without real-time analysis, much remains unclear. Which systems consume disproportionate amounts of energy? Which products or product ranges drive consumption particularly high? Without transparent data, there is no basis for identifying inefficiencies and making targeted optimizations. Decisions are often based on assumptions rather than facts, while rising energy costs and legal requirements create additional pressure. Those who lack clarity about current consumption risk wasting valuable resources and missing opportunities for cost reduction.

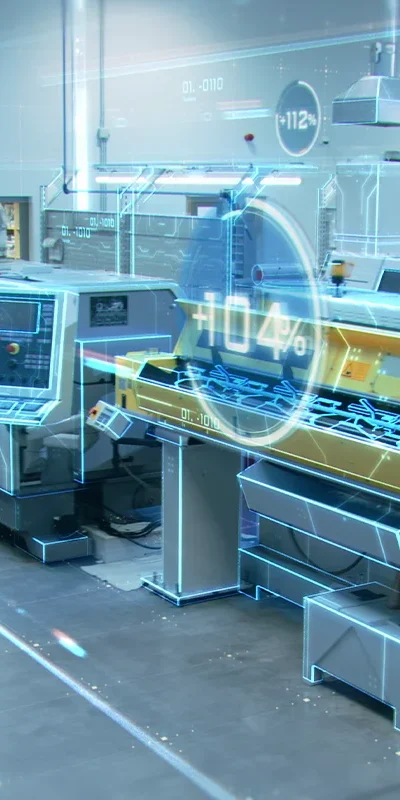

Transparency and Control Through Real-Time Analytics

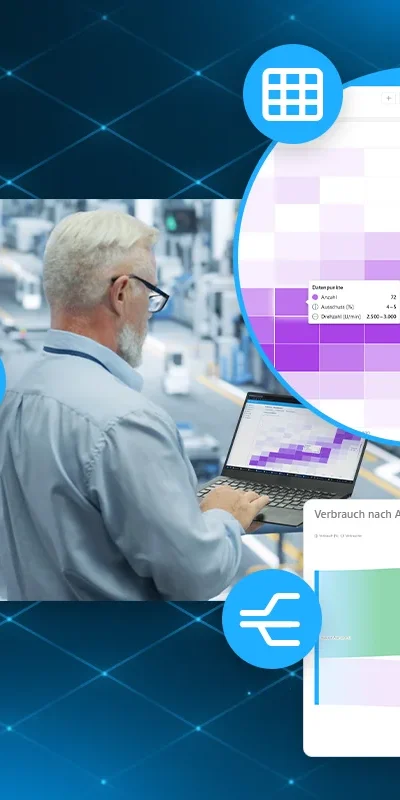

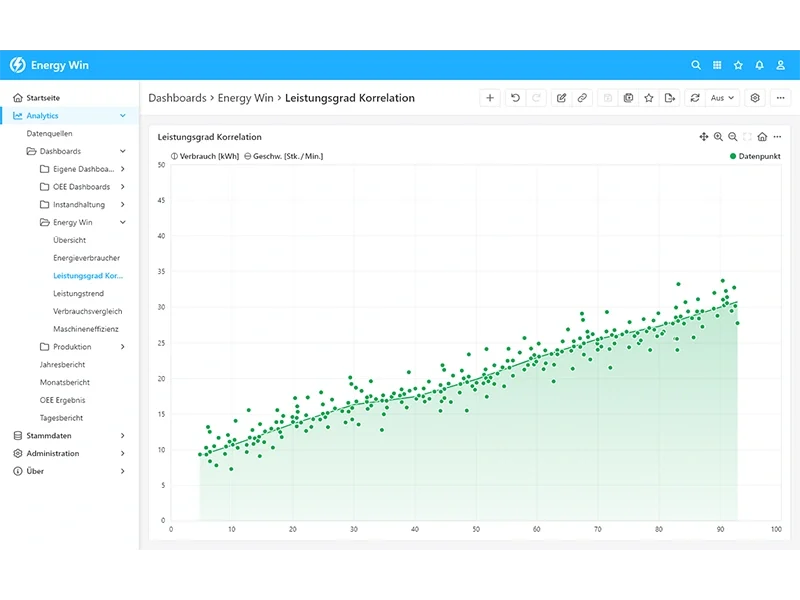

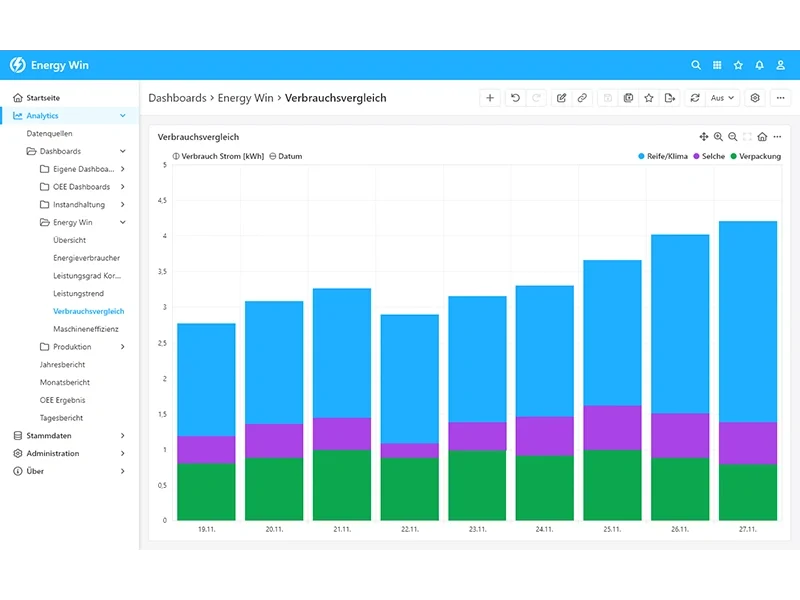

Software that enables real-time analytics and precise evaluations is revolutionizing energy and consumption optimization in manufacturing companies. It provides clear insights into the consumption of individual machines, systems, or even product- and product-specific processes. This transparency allows inefficient systems to be quickly identified, targeted measures to be implemented and resources to be used more efficiently. At the same time, historical data enables informed decisions for strategic direction. Such tools can reduce costs, achieve sustainability goals and permanently optimize processes – an essential foundation for modern production.

Key Features

- Real-time energy consumption localization

- Continuous energy consumption transparency

- Basis for energy control management

- Targeted consumption and cost optimization

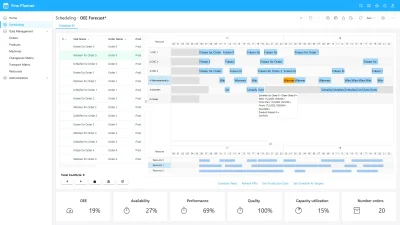

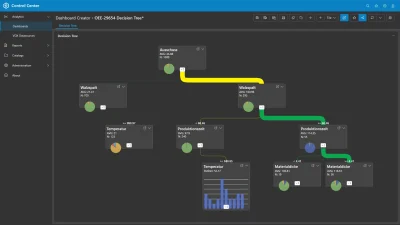

Expansion Options (with OEE Analyser)

- Integration with common machine data acquisition systems for productivity comparison

- Product-related energy consumption and energy cost transparency

- Production control with the highest level of transparency

“The energy crisis is currently on everyone’s lips. With Energy Win, we want to make a decisive contribution to helping our customers avoid wasting energy as much as possible.”

Martin Stimpfl CEO