Shop Floor Management

Why Is This Important?

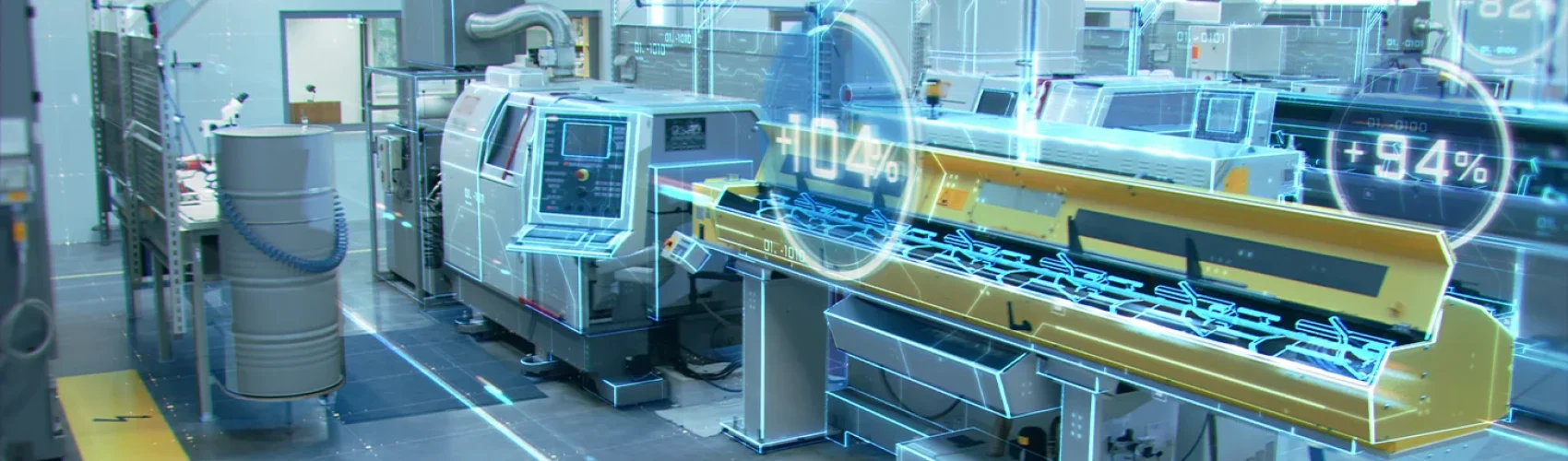

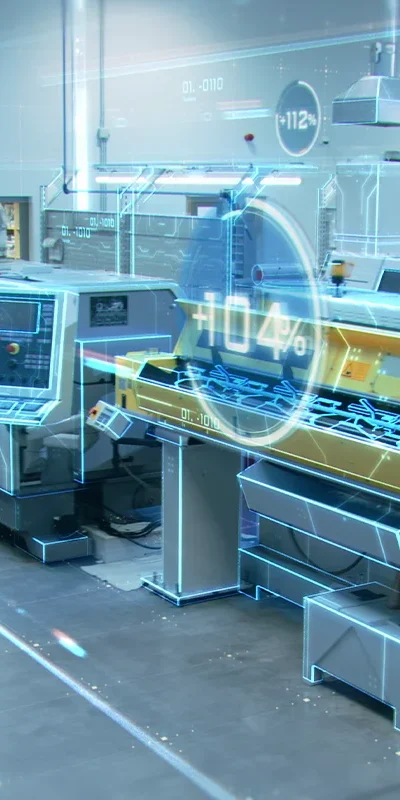

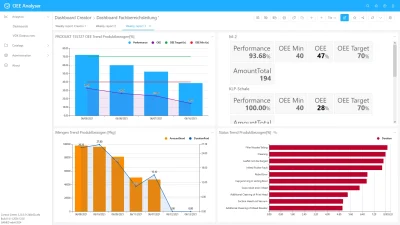

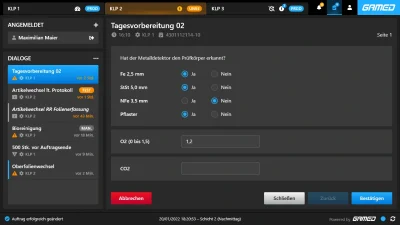

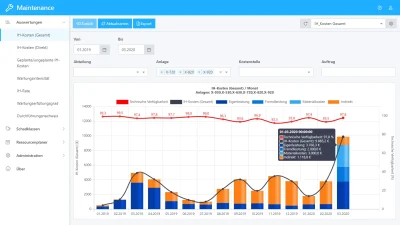

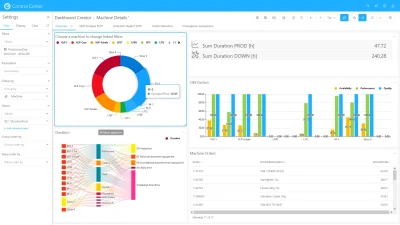

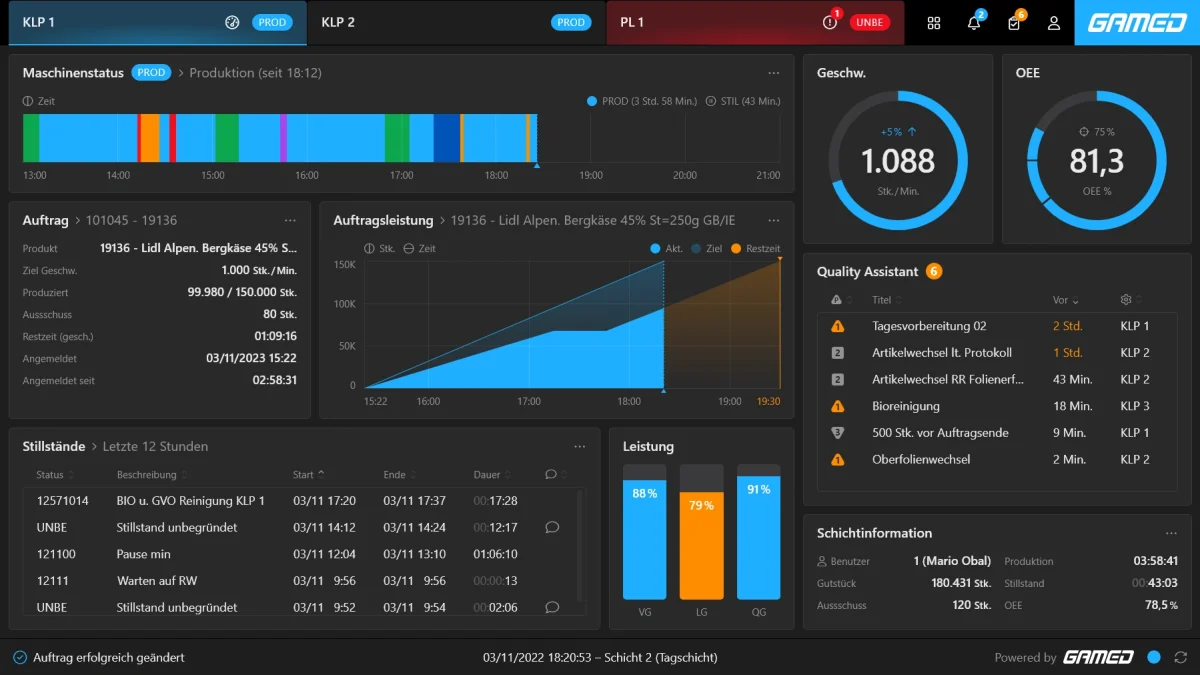

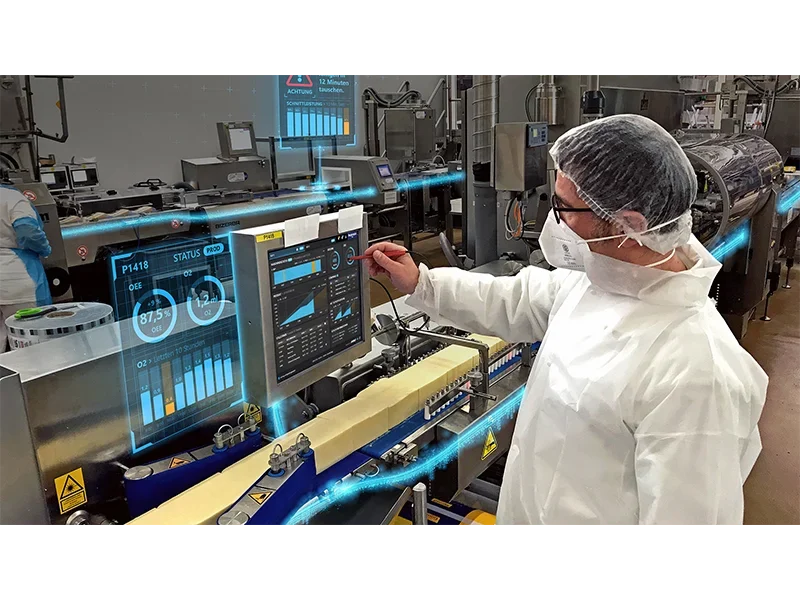

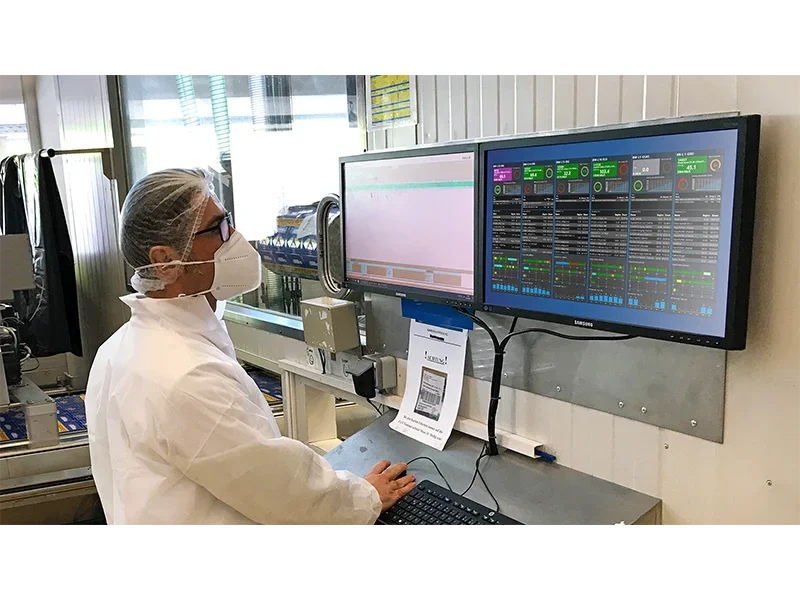

Digital shop floor management uses software to visualise production and operational data based on historical and current real-time values. It enables management to communicate its vision in a structured manner to departments and employees.

By connecting departments, a vertically and horizontally integrated system is created that provides a clear overview of the entire production process as well as specific sub-areas. This promotes transparency, faster decision-making and more efficient collaboration at all levels.

Economic Benefits

- Increased efficiency and cost reduction: Real-time monitoring and data-based decisions optimise production processes, minimise downtime and use resources more efficiently. This reduces costs for scrap, energy and unplanned maintenance.

- Better decision-making basis and higher productivity: The combination of real-time and historical data enables well-founded decisions. Bottlenecks and problems are recognised early, reducing response times and increasing overall productivity.

- Increased transparency and improved collaboration: Vertical and horizontal networking ensures that everyone involved – from management to production – has a common understanding of the situation. This promotes cross-departmental coordination and an agile way of working.

Key Features

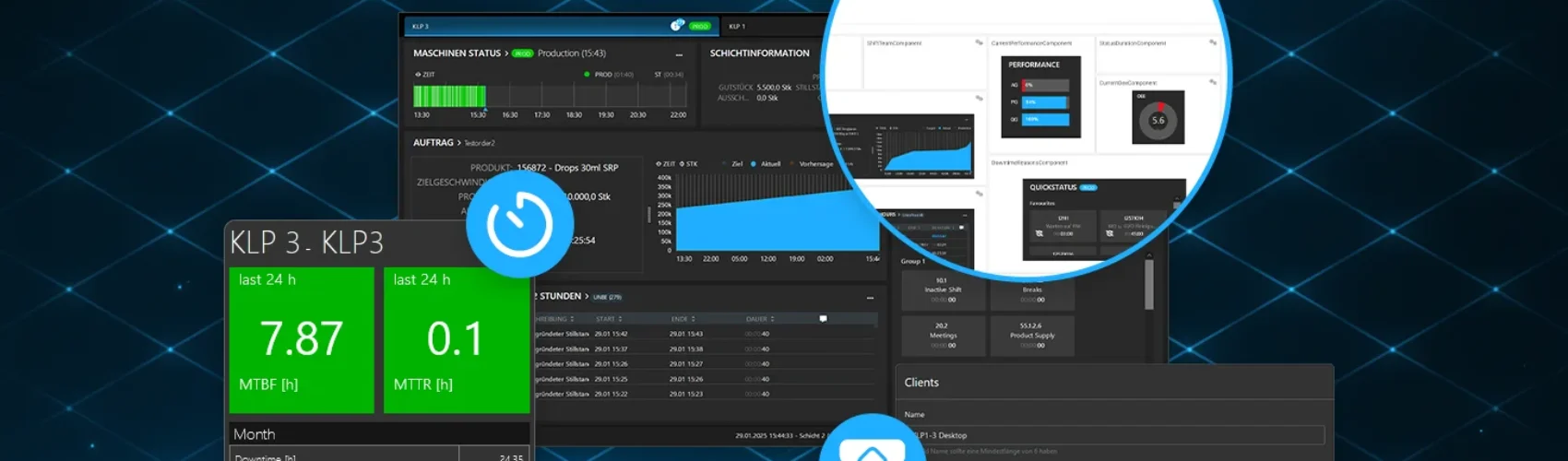

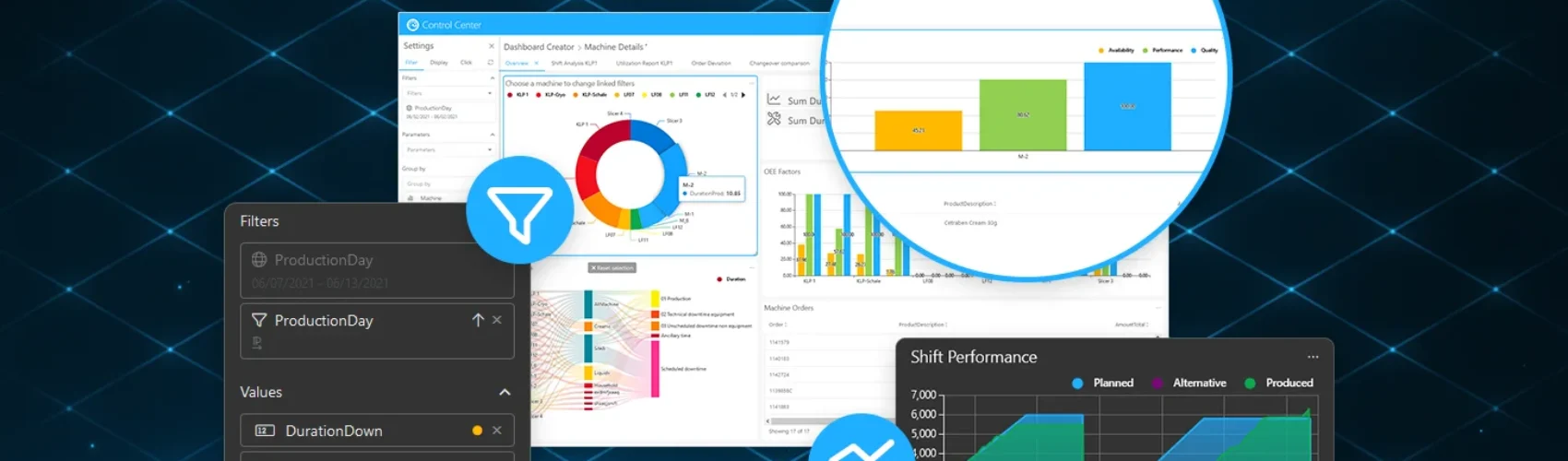

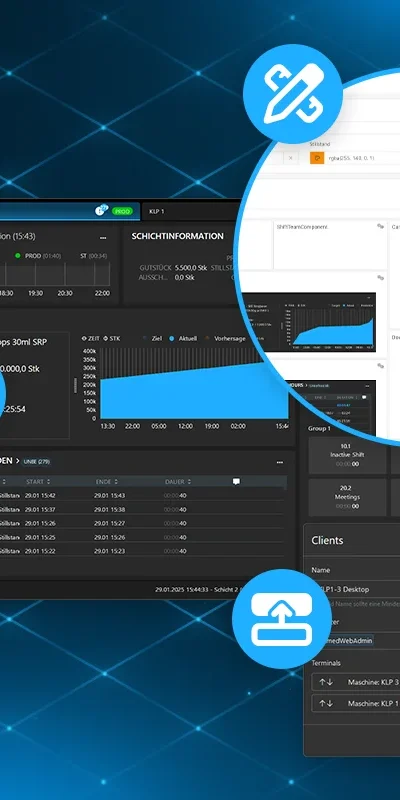

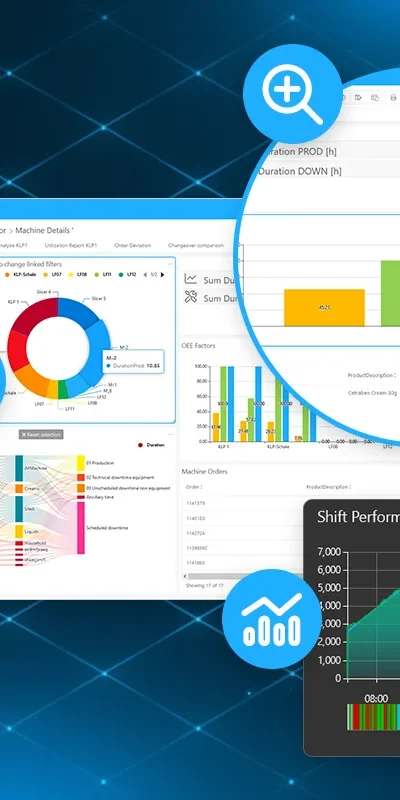

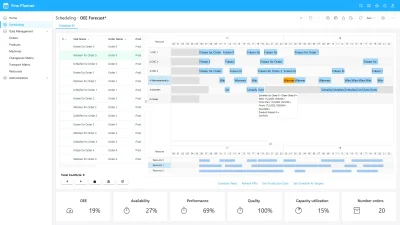

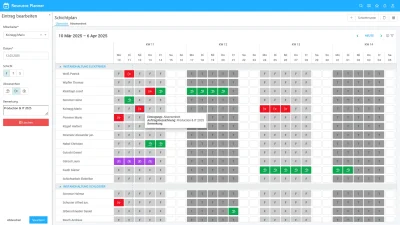

Our system not only enables visualisation on large screens, andon boards, tablets and smartphones, but also ensures the seamless integration of third-party software through our wide range of interfaces and communication options.

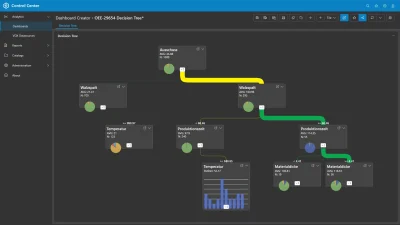

This enables vertical integration of historically grown software solutions and helps to analyse the causes of productivity deviations.

With functions such as drill-down, drill-through and broadcasting, the shop floor dashboards automatically adapt to the altitude at which they are viewed. This allows you to quickly gain a global overview of all locations, right down to the plant level of a specific production environment within your own organisation.

“Our digital shop floor management makes production data tangible – we combine vision with practice and create real efficiency for our customers.”

Roland Wetzl Head of Sales