What’s new?

Newswall

-

![40 Jahre Jubiläumsfeier 1 40 Jahre Jubiläumsfeier 1]()

-

![MolkereiForum 2025-2 MolkereiForum 2025-2]()

-

![KPIs and process values in focus 2025-11 KPIs and process values in focus 2025-11]()

28. November 2025

KPIs and Process Values in Focus

Did you know? With our flexible data acquisition component MDA (Machine Data Acquisition), you can capture any process …

Roland Wetzl

-

![Update Highlights 2025-11 Update Highlights 2025-11]()

25. November 2025

Update Highlights 2025-11

Did you know? With our flexible data acquisition component MDA (Machine Data Acquisition), you can capture any process …

Roland Wetzl

-

![Halloween 2025 Halloween 2025]()

-

![Privatmolkerei Bauer Success Story 2025 Privatmolkerei Bauer Success Story 2025]()

-

![MolkereiForum 2025 Preview MolkereiForum 2025 Preview]()

-

![EcoVadis 2025 EcoVadis 2025]()

-

![FELIX and GAMED: Productivity boost at Privatmolkerei Bauer FELIX and GAMED: Productivity boost at Privatmolkerei Bauer]()

-

![Barbecue 2025 Barbecue 2025]()

-

![Release Notes Release Notes]()

25. April 2025

Release Notes

Our release notes contain constantly updated technical information as well as information on new functions, improvements and fixed bugs in our software solutions.

Roland Wetzl

-

![LSZ Production & IT 2025 LSZ Production & IT 2025]()

-

![Skiwochenende Schladming 2025 Skiwochenende Schladming 2025]()

-

![Cyber Trust Austria Zertifizierung Cyber Trust Austria Zertifizierung]()

-

![LSZ Production & IT 2025 Ankündigung LSZ Production & IT 2025 Ankündigung]()

-

![Köstliches Neujahrsessen Köstliches Neujahrsessen]()

-

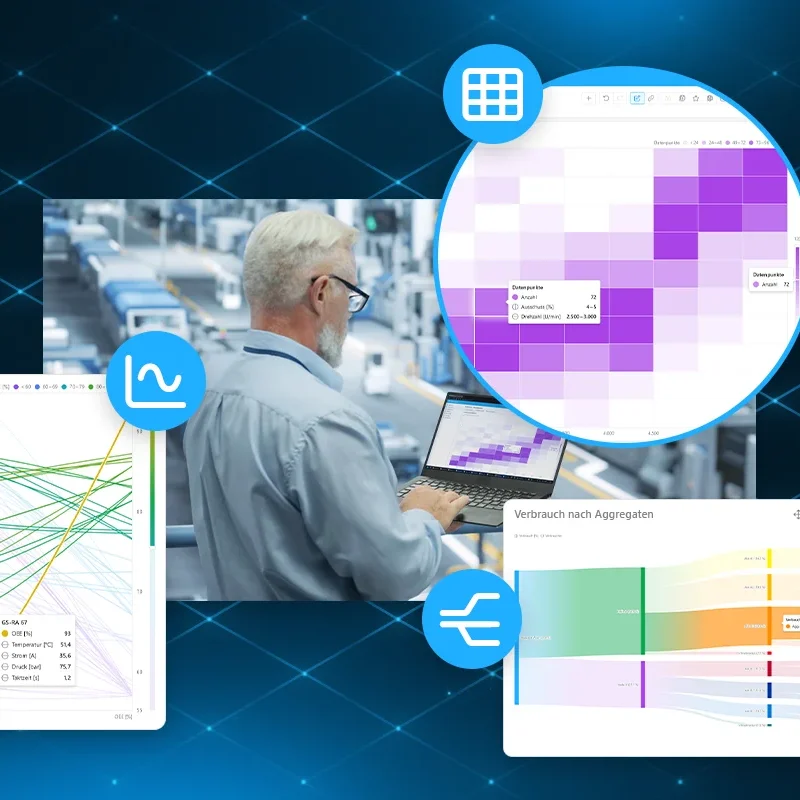

![Data Analytics Update Highlights 2025-01 Data Analytics Update Highlights 2025-01]()

31. January 2025

Data Analytics Update Highlights

The new release offers you powerful features such as drill-down for detailed analyses, drill-through for seamless data …

Roland Wetzl

-

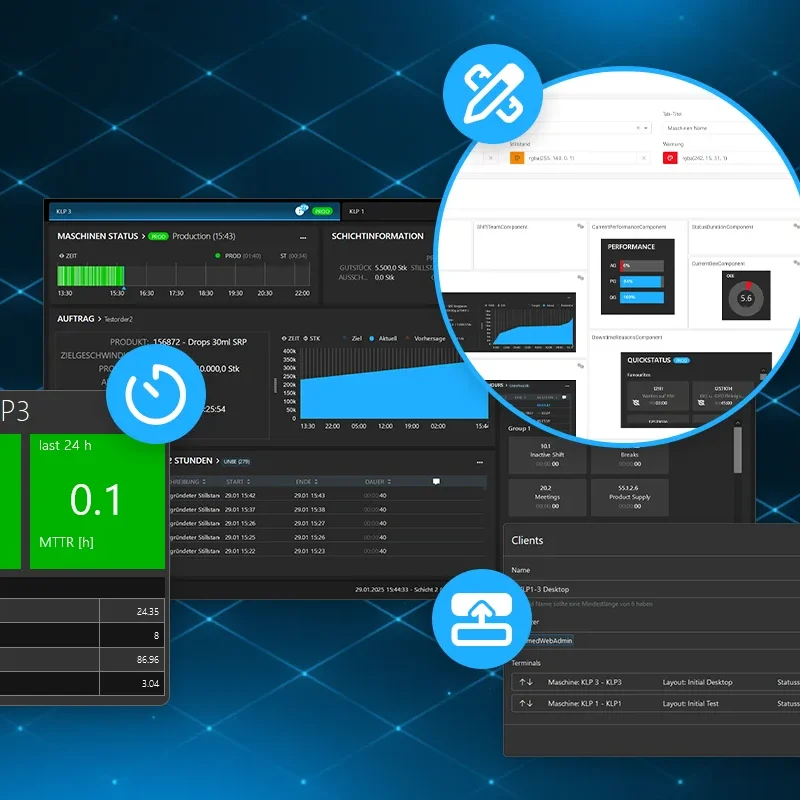

![Shopfloor Management Update Highlights 2025-01 Shopfloor Management Update Highlights 2025-01]()

29. January 2025

Shop Floor Management Update Highlights

The new release offers you innovative functions such as automatically calculated MTBF and MTTR, anonymous counters …

Roland Wetzl

-

![Control Center Update Highlights 2025-01 Control Center Update Highlights 2025-01]()

27. January 2025

Control Center Update Highlights

In the first release 2025, you can look forward to numerous improvements that will bring you real added value. Discover …

Roland Wetzl

-

![Happy new year 2025 Happy new year 2025]()

-

![Merry Christmas Merry Christmas]()

-

![Fleißige Weihnachtswichtel Fleißige Weihnachtswichtel]()

-

![Führungskräfte Workshop 2024-11 1 Führungskräfte Workshop 2024-11 1]()

-

![Halloween 2024 Halloween 2024]()

-

![Efficiency in production as a driver of sustainability Efficiency in production as a driver of sustainability]()

-

![Success Story Berglandmilch Success Story Berglandmilch]()

-

![Ausflug Buschenschank Ausflug Buschenschank]()

-

![Schöne Urlaubsgrüße Schöne Urlaubsgrüße]()

-

![Sieger EM Tippspiel Sieger EM Tippspiel]()

-

![Barbecue 2024 Barbecue 2024]()

-

![Kommunikationstraining Teil 1 Kommunikationstraining Teil 1]()

-

“Our success is based on the consistent application of TPM and quality management throughout the entire team. The MES solution from GAMED serves us as a reliable information hub in the plant.”

DI Silvia Schneller Deputy Operations Manager

-

![GLi-Symposium 2024 GLi-Symposium 2024]()

-

![Sponsoring Radlager Enzi-Trail Sponsoring Radlager Enzi-Trail]()

-

![LSZ Production & IT 2024 LSZ Production & IT 2024]()

-

![Skiwochenende Schladming 2024 Skiwochenende Schladming 2024]()

-

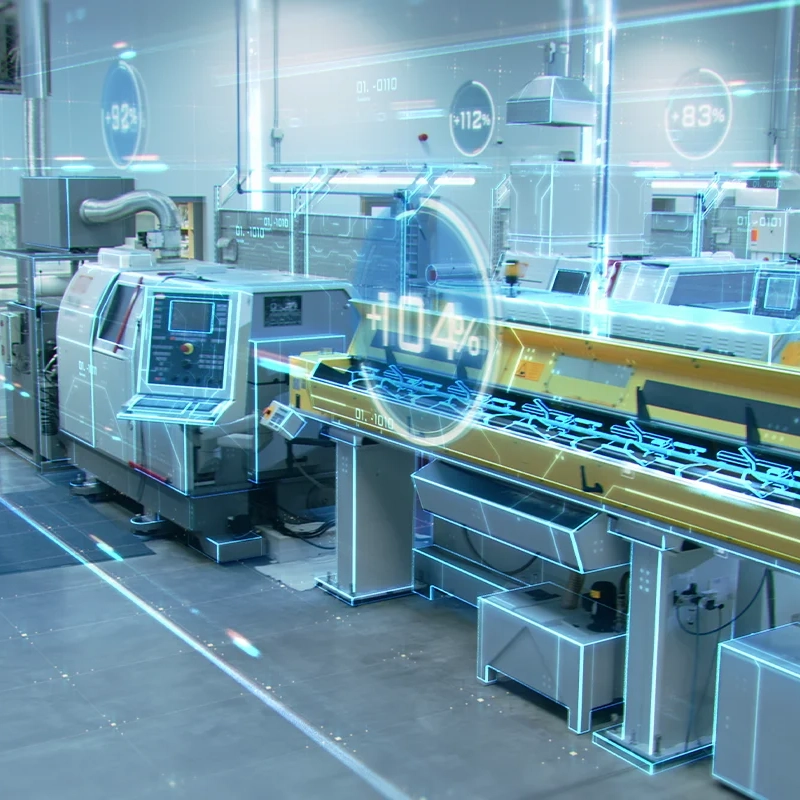

![Paths to digital production Paths to digital production]()

16. February 2024

Paths to Digital Production

Process control, transparency and greater efficiency are the goals of digital production and make companies more competitive. The …

Roland Wetzl

-

![Fasching 2024 Fasching 2024]()

-

![Valentinstag 2024 Valentinstag 2024]()

-

![Vorweihnachtliches Get-together Vorweihnachtliches Get-together]()

-

![Böhler Werksführung Böhler Werksführung]()

-

“Continuous improvement is better than delayed perfection.”

Mark Twain Writer

-

![Silvester 2023 Silvester 2023]()

-

![Weihnachten 2023 Weihnachten 2023]()

-

![Future Engineers 2023 Future Engineers 2023]()

-

![Appletinies Appletinies]()

-

![OEE (Overall Equipment Effectiveness) OEE (Overall Equipment Effectiveness)]()

12. November 2023

OEE (Overall Equipment Effectiveness)

The term Overall Equipment Effectiveness (OEE) refers to a key figure that is used to determine the productivity of operating …

Roland Wetzl

-

![Polos Polos]()

-

![Buschenschank Tschermonegg Buschenschank Tschermonegg]()

-

![Halloween 2023 Halloween 2023]()

-

![Exit The Room Exit The Room]()

-

“We also owe our success to our partnership with GAMED. The software products and technical expertise are now important elements in our global programme for operational excellence.”

Paul Booth Director of Operations

-

![NEW BUSINESS ConfirmD NEW BUSINESS ConfirmD]()

-

![Biken Biken]()

-

![Urlaubsgrüße Urlaubsgrüße]()

-

![Barbecue 2023 Barbecue 2023]()

-

![OEE in Industrial Practice: Opportunities and Limitations OEE in Industrial Practice: Opportunities and Limitations]()

09. August 2023

OEE in Industrial Practice: Opportunities …

OEE (Overall Equipment Effectiveness) was developed as part of the TPM concept in the 1960s and is used to determine …

Roland Wetzl

-

![Office Improvements Office Improvements]()

-

![Women's Day Women's Day]()

-

![GLi-Symposium 2023 GLi-Symposium 2023]()

-

![GLi Symposium 2023 GLi Symposium 2023]()

17. May 2023

GLi-Symposium 2023 Review

The days from 22 to 23 March were dominated by the GLi Symposium, which brings together the companies of the “Non-profit Food …

Roland Wetzl

-

![Elena Mutterschutz Elena Mutterschutz]()

-

![Fasching 2023 Fasching 2023]()

-

![Ende Papamonat Ende Papamonat]()